In this blog, I have shown pitcher forms before, but have not gone into detail about how they are made or how the form has evolved during the making.

This is a very small free form hand pitcher made from a slab with impressed design using a swizzle stick, a sea shell, and a bit of styrofoam packing material.

To make the pitcher, I cut out a bottom freehand in an oval-ish shape, then curved the body of the pitcher slab around the edge of the bottom to fit. I used the clay worm method to seal the sides and bottom together, closing the form with one seam at the front where the spout will go.

I cut a V shape in the front to fit the small hand-formed spout. I left evidence of the cut. I liked that and made a note in my mind to repeat it.

The glaze is celadon and the body is porcelain.

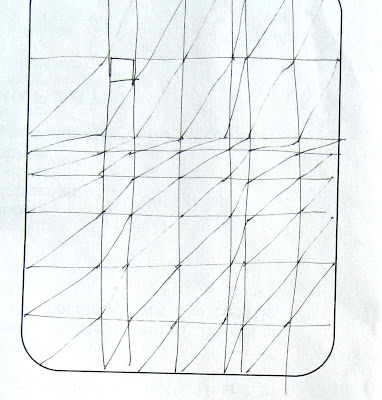

This is a later version of a more distinct surface treatment. This time I added two new patterns; a combed effect. The checked texture is from a scrap of plastic that I picked up in a parking lot. Must have been a part of a tail light….

This is a later version of a more distinct surface treatment. This time I added two new patterns; a combed effect. The checked texture is from a scrap of plastic that I picked up in a parking lot. Must have been a part of a tail light….The basic construction is the same as the hand pitcher shown above, but the body shape was drawn out on a piece of paper before assembly.

There is only one seam in this pitcher also under the spout. This is the beginning of new thinking about spout shapes.

During assembly, I decided there was too much stress on the dip area between the spout section and the back section, so I added a reinforcement 'button' to keep it from splitting. It makes a nice transition element in the design.

The hand fits nicely around the back of this pitcher with the curve resting easily on the hand between the thumb and fingers.

The body is porcelain and the glaze is a semi transparent rutile.

In this case, I made the seam down the side instead of under the spout and cut a hole for the spout.

The same technique of cutting out the base first, then forming the body from one slab piece was followed and the spout is also hand-formed.

I pooched out the bottom a bit to give it weight.

This piece served as a glaze test as well. I liked the texture of the slab roller matt showing under the glaze. I named this piece "Black Nose" in my mind.

Another look at an earlier slabbed approach. Basically taking the same form and making two vessels into a creamer and sugar.

Another look at an earlier slabbed approach. Basically taking the same form and making two vessels into a creamer and sugar.The forms are a bit more free and I was playing around more with altering the body and adding feet made of rolled clay.

It is also a glaze experiment using a white body and drizzling a dark brown glaze over edges of the form.

This is a medium sized pitcher and a very early piece. My main experiment was working with the relationship of the handle and the spout.

I wanted them to be the same size and I used the same trusty texture-making tools here. But the difference is the weight and thickness of the glaze. So the pattern comes off a bit more muted.

And the handle is the beginning of thoughts about using rolled clay and the attachment process for a vessel.

This is a larger pitcher form, but here in the the watering can version. I am still experimenting with the spout and handle idea and also using texture on the exterior.

The thicker glaze mutes the surface more than I wanted, but the ideas of spout and handle are still being explored.

This piece is also in porcelain and the glaze is a version of weathered bronze.

The seam is still at the front of the piece and the spout is cut in and attached.

A new approach; using a thrown form and keeping the handle/spout forms only refining them. This time I'm cutting both the places where the handle attaches to the top rim as well as where the spout attaches.

I again used the reinforcing 'button' at the split for the top of the handle. The spout is laid into the front split and blended into the body of the pitcher.

The new spout form is an imitation of a tropical leaf form; designed to shed water. It works very well.

I love the break in the glaze. It is Coyote Crocodile glaze fired at cone 5 OX. This is a slightly larger pitcher and it's a keeper.

The next pitcher is the same technique and form, but what a difference a glaze makes!

A slight modification to the form is the elevation of the base with the use of a bevel tool at the end of throwing. It improves the overall look of the piece, I think.

The clay is porcelain and the glaze is three different shinos.

This is one of my favorite pitchers.